Cong flags concerns about automobile sector stagnation

“Car purchases in India are largely limited to the top 12% of households with an annual income exceeding Rs12 lakh, while even small cars have become unaffordable for the remaining 88%."

In the realm of safety, regulatory, and policy considerations, fostering a hydrogen economy is imperative as safety serves as the linchpin for its promotion.

Dr. JP Gupta | New Delhi | December 11, 2023 8:32 am

Representative image

In the realm of safety, regulatory, and policy considerations, fostering a hydrogen economy is imperative as safety serves as the linchpin for its promotion. The repercussions of neglecting safety are multifaceted, influencing not only GDP but also posing threats to human life, triggering adverse environmental impacts, jeopardizing business reputation and success, and even tarnishing a country’s image, thereby hindering investment prospects. Additionally, it can instil fear in communities, rendering society less tolerant to avoidable accidents.

Safety is a critical consideration in the new energy (Green Hydrogen)sector to achieve decarbonization. The green hydrogen economy involves the production, storage, transportation, and utilization of hydrogen, and each of these steps poses potential safety challenges.

Advertisement

Here are several reasons highlighting the importance of safety in the green hydrogen economy: Delving into basic facts, recent data on fire incidents in India, revealing 1.6 million fires and 27,027 deaths, raises concerns. When compared with international cases, India’s death toll is 2.5 times higher than China’s. The inadequate corporate governance in process safety exacerbates these risks.

Advertisement

To address this, there is a pressing need toimplementmodern tools in quantitative risk analysis and risk management, encompassing training, capacity building, and innovation. Use of Virtual Reality (VR) basedtrainingmodules is essential for effective safety training. How dangerous is Hydrogen? Hydrogen differs from substances like hydrocarbons, and needs to be handled differently;

* It is extremely buoyant, 14 times lighter than air, and rises six times faster than natural gas;

* Odourless and non-toxic;

* Gas at ambient conditions, cryogenic liquid;

* Wide flammability range: 4- 75% (methane 5-15%);

* Very small molecules – leaks easily; * Laminar burning velocity about 3 m/s, which is six times faster than hydrocarbon gases;

* Low ignition energy: 0.02 mJ, which is about 10 per cent of the ignition energy for hydrocarbon gases;

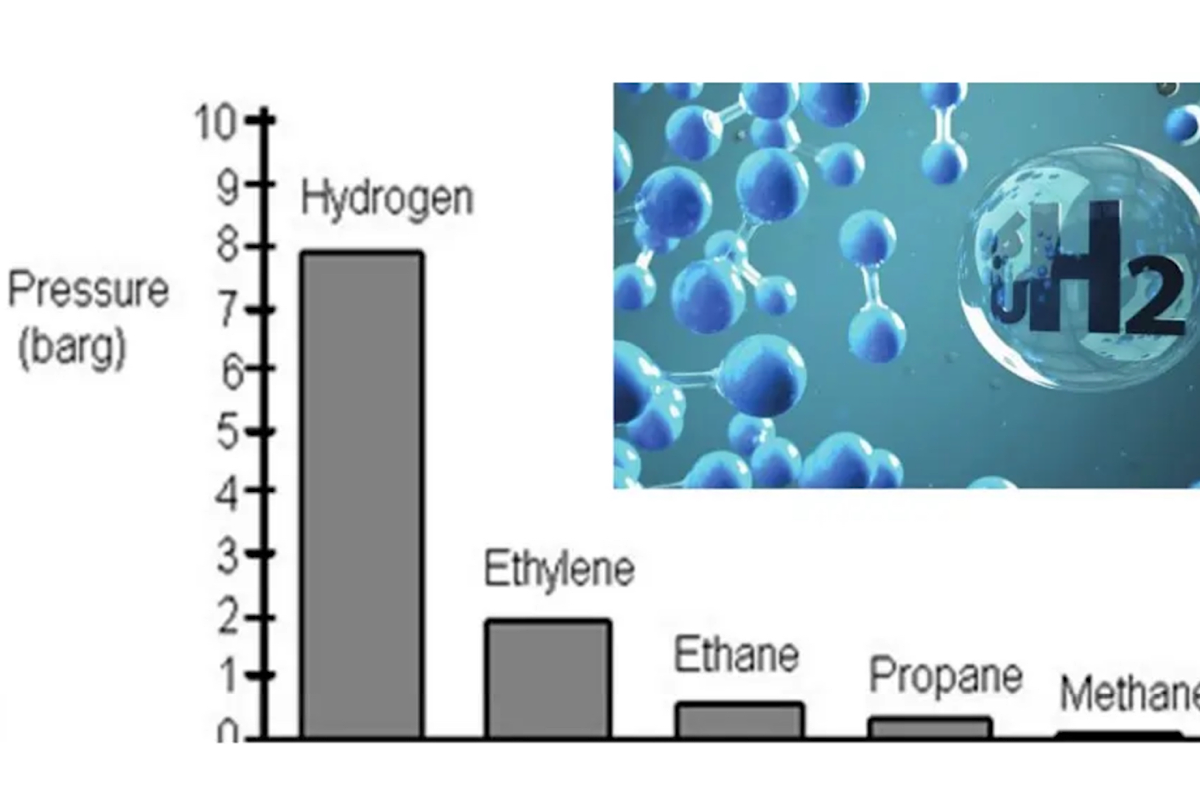

* Negative Joule-Thompson effect and possibility for autoignition of leakages from high pressure. We need to gain knowledge, develop designs and operating procedures, so that hydrogen can be implemented as an energy carrier without unacceptable societal risk How does hydrogen compare to other gases? The chart publishes alongside makes this clear.

However, while acknowledging that there are knowledge gaps in hydrogen safety, ongoing research aims to fill these voids, covering aspects such as hydrogen jet fires, liquid hydrogen pool formation, rapid phase transitions, BLEVEs, evaporation and fires from liquid hydrogen pool, transition from deflagration to detonation, establishing correlation between reservoir pressure, aperture geometry, leakage rate, probability for spontaneous ignition, and more.Experimental work and model development is required.

Currently, FLACS is the only CFD-based safety analysis software validated for hydrogen. New experimentsneed to be conducted to make FLACS cover gaps. Hydrogenis a not-so-new energy carrier. Some facts are noteworthy.

* H2 has been produced and used for a hundred years – what is new?

* It was used in controlled industrial environments with strict safety regulations;

* In the future, transport and other “domestic” uses would put hydrogen much closer to the public.

To ensure safe handling, stakeholders must pursue and promote safety improvements beyond standards and regulations. They are perhaps not there yet. They must also promote cross-industry learning, and ensure that all are aligned to the safety objectives. And finally, accidents will happen; stakeholders must ensure they learn from them. A global approach calls for the following: Continuousresearch for safe design, including

* Industry, government and universities/institute collaborations;

* Development of ‘Centers of Excellence’ (examples of USA, UK, Germany, China and Norway etc.)

* Emphasis from the boardroom to the front line * Make safety second nature

* Ongoing research to ensure inherent safe and reliable designs

* Prevention of accidents Effective Accident Response

* Minimize damage through VR training for fire-fighters, employees and disaster management teams Global Use of 3D Models and VR

* Advanced use of 3D models globally for risk assessment * VR employed to create realistic training scenarios Topmost Priority to Process Safety * Process safety given the highest priority in all activities

* Aims to establish a strong ecosystem for sustainable safety Coming now to regulatory and policy issues, there should be one safety directorate for effective co-ordination rather than shared responsibilities with several ministries as follows; I.

The Ministry of Consumer Affairs, Food and Public Distribution:Bureau of Indian Standards (BIS) is involved in developing standards and specifications for hydrogen production, storage, and transportation; II. The Department for Promotion of Industry and Internal Trade (DPIIT):

Petroleum and Explosives Safety Organization (PESO) under DPIIT is the nodal agency for regulating safety of hazardous substances such as explosives, compressed gas and petroleum; III. Ministry of Road Transport & Highways (MoRTH): This is the nodal ministry for regulation of the automotive sector in India; IV. Oil Industry Safety Directorate (OISD):This is a technical directorate under the Ministry of Petroleum and Natural Gas (MoPNG); V. The Petroleum and Natural Gas Regulatory Board (PNGRB):PNGRB’s role would be crucial for regulating hydrogen blending in natural gas pipelines; VI. Statewise Directorates of Industrial Safety & Health. In conclusion, it may be said that the imperatives are

* Developing skilled persons through VR;

* Database for all accidents;

* Audit for higher learning after each accident;

* Follow International Standards, till the Indian Standards are formulated;

* Corporate Governance in safety from Board Room to Front Line;

* Setting up of Centres of Excellences in each state in India for Training, Capacity Building and Innovation.

* Given the global nature of the hydrogen economy, international cooperation on safety standards and best practices is essential. Collaborative efforts can help establish a consistent and robust framework for ensuring safety across borders.

* Ongoing research and development in hydrogen technologies should prioritize safety innovations. This includes advancements in materials, storage systems, and production methods that enhance safety while maintaining efficiency and cost-effectiveness.

DR. J P GUPTA The writer is Chair, Environment & Green Hydrogen Committee, PHDCCI, and Managing Director, Greenstat Hydrogen India Pvt. Ltd. He can be reached at jpglobalconsultinggroup@gmail.com

Advertisement

“Car purchases in India are largely limited to the top 12% of households with an annual income exceeding Rs12 lakh, while even small cars have become unaffordable for the remaining 88%."

India continues to remain the world’s fastest-growing major economy and the only country expected to clock over 6 per cent growth in the next two years, according to an IMF report released on Tuesday, which has trimmed the growth forecast for over 120 countries.

Fitch Ratings cut India's GDP growth estimate by 10 basis points to 6.4 per cent for the current fiscal.

Advertisement