More women now seeking credit, monitoring their credit scores: NITI Aayog report

NITI Aayog on Monday launched the report titled “From Borrowers to Builders: Women’s Role in India’s Financial Growth Story”.

in India, it is estimated that circular economy may provide opportunities worth $218 billion per year by 2030. According to NITI Aayog, fast increasing human population will raise the total global mineral and material demand from 50 billion tonnes in 2014 to 130 billion tonnes in 2050. For sustainable development, resource efficiency and circularity is imperative

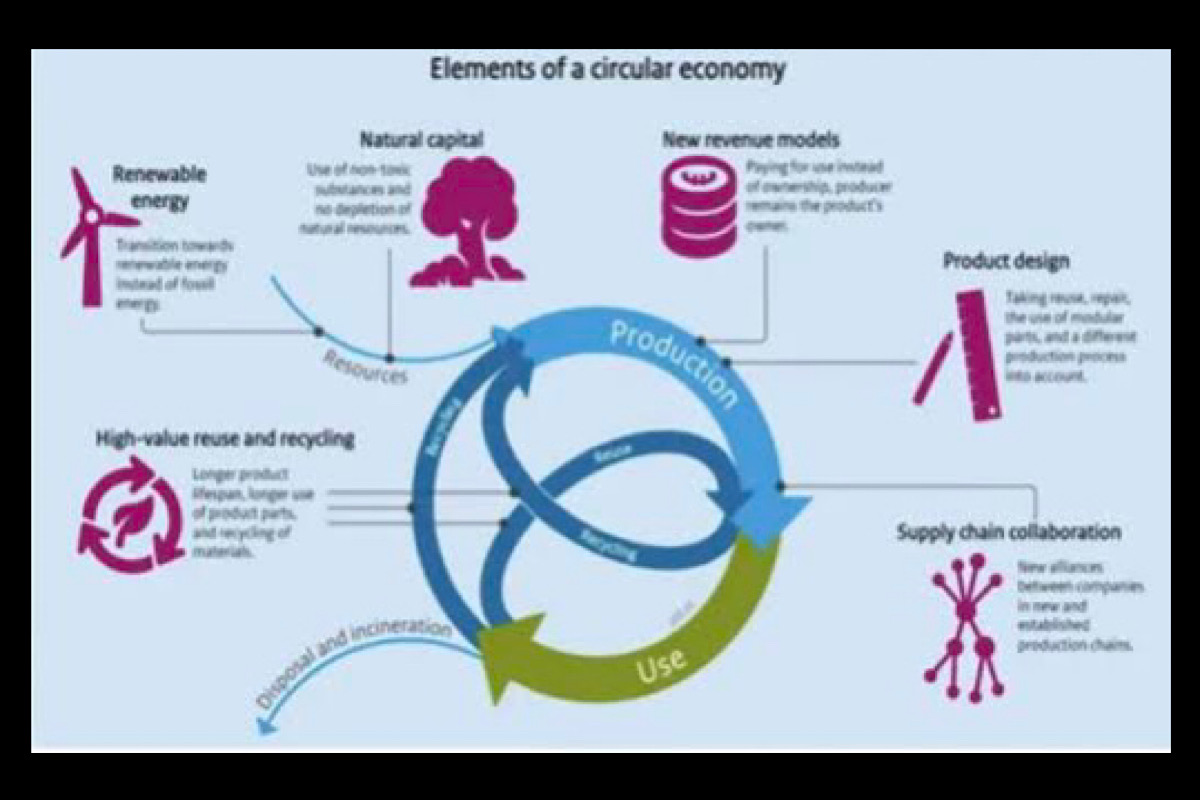

Figure 1: Some of the elements of a circular economy mentioned above and others in relation to each other (Source: PBL, 2019)[Photo:SNS]

India aspires by 2025 to be a five trillion-dollar economy that would generate business and new entrepreneurs. This would also increase resource and energy consumption and waste generation.

To achieve the target of a five trillion-dollar economy in tune with sustainable development principles, it is necessary to ensure low carbon footprints for climate-change. Principles of circular economy will be the key driver to achieve this mission.

Advertisement

Circular systems emphasise reuse, repair, refurbish, remanufacture and recycle, thereby minimizing wastes that reach landfills or incinerators, reducing carbon emissions and utilizing clean energy. In contrast to the linear systems that have been working on the concept to create, use and dispose, the circular system is a closed-loop system where the use of created products is extended, useful parts of the old equipment are suitably used in refurbishment of same or other type of equipment or for creating new ones.

Advertisement

Such materials reduce the need of fresh raw materials, resources, energy (retain embedded energy) and the polluting processes. The wastes of a process or a by-product are used as raw material for the other process or there is resource recovery for manufacturing of a new product. This prevents the waste from going to landfill sites or incinerators.

Only the residual material not worth using again and again goes to the landfill/ incinerator.The non-toxic biological materials are returned to the soil. Circular economy can be implemented in all sectors. The ‘regenerative’ approach of circular economy is in contrast to the throw-away attitude of capitalist society of ‘make, use and dispose’.

The developing world has been observing circular strategy since long due to lack of resources and has been reusing, recycling and remaking objects with same or different use. This saves on the material and other costs. * Reduce (minimum use of raw materials) * Reuse (maximum reuse of products and components) * Recycle (high quality reuse of raw materials) With the environment law enforcing agencies enacting stringent environment laws, many vehicles not conforming to these will go off the roads. This provides immense opportunities for circular strategies to remake vehicles with old parts of abandoned vehicles.

Plastic industry is another important sector for the circular economy. Globally, 8.3 billion tons of plastic was produced between 1950-2015. Out of 6.3 billion tons which became waste, 4.9 billion tons reached the dumpsites. With the increasing trend of plastic manufacturing, an estimated 12 billion tons of plastic will be dumped in the environment by 2050.

Circular strategy in the closed-loop system encourages its reuse, recycle, remanufacturing and finally safe disposal. Plastic can be used for thermal insulation of houses. In India, major industries dealing with plastic have come together last year to form an alliance against plastic waste.

India recycles or reuses over 90 per cent of all the PET (polyethylene terephthalate plastic) manufactured in the country. India has also shown improved electronics recycling.

By signing ‘extended producer responsibility’ more than 700 electronics producers have come together to reduce e-waste. There is huge scope of reusing, repairing, refurbishing, remaking and recycling in the textile industry. Craze for new varieties and styles have pushed the young generation into buying surplus clothes.

The owner’s utilization time and recycling of the clothes is very low due to which natural resources of more than $500 billion are lost every year, according to experts. Economic analysis shows that three important areas, viz. cities and construction, food and agriculture, and mobility and vehicle manufacturing could bring annual benefits of a Rs 40 lakh crore-worth circular economy by 2050. India’s material consumption is expected to rise from 7.5 billion tons in 2015 to 15 billion tons in 2030.

India’s rate of resource extraction, including mining of virgin resources, is nearly three times higher than the global average. In light of this, resource efficiency and waste management can bring down consumption and waste to almost nil. This will result in huge reduction in millions of tonnes of waste and CO2 emissions.

The government policy enables reuse of waste and redouble recycle rate of key materials to 50 per cent in five years. It envisions setting up a National Resource Efficiency Authority, which like the Bureau of Energy Efficiency, will offer strategies for key sectors ~ automobiles, plastic packaging, building and construction, electrical and electronic, equipment, solar photo-voltaic, and steel and aluminium to begin with.

To implement circular economy principles and circular economy strategies in organisations, the British Standards Institution (BSI) had launched the standard ‘BS 8001:2017’. India is realising the importance of having its own regulatory framework such as National Material Recycling Policy, National Policy on Resource Efficiency, Bureau of Resource Efficiency (BRE) etc.

There is a need to integrate resource circularity in the Industrial Revolution (IR) 4.0 strategies. In India, it is estimated that circular economy may provide opportunities worth $218 billion per year by 2030. According to NITI Aayog, fast increasing human population will raise the total global mineral and material demand from 50 billion tonnes in 2014 to 130 billion tonnes in 2050. For sustainable development, resource efficiency and circularity is imperative.

Produce, consume and discard needs rejuvenation. Resource efficiency and waste management will need to be the key drivers of a green strategy, because it is now the only viable path, capable of creating growth, new enterprises, and a clean environment.

The writer is Chair, Environment and Green Hydrogen Committee,PHD Chamber of Commerce & Industry and can be reached at pglobalconsultinggroup@gmail.com

Advertisement