Indian Institute of Technology (IIT) Mandi researchers have developed indigenous technology for recycling and manufacturing high-efficiency face masks from waste ‘PET’ bottles.

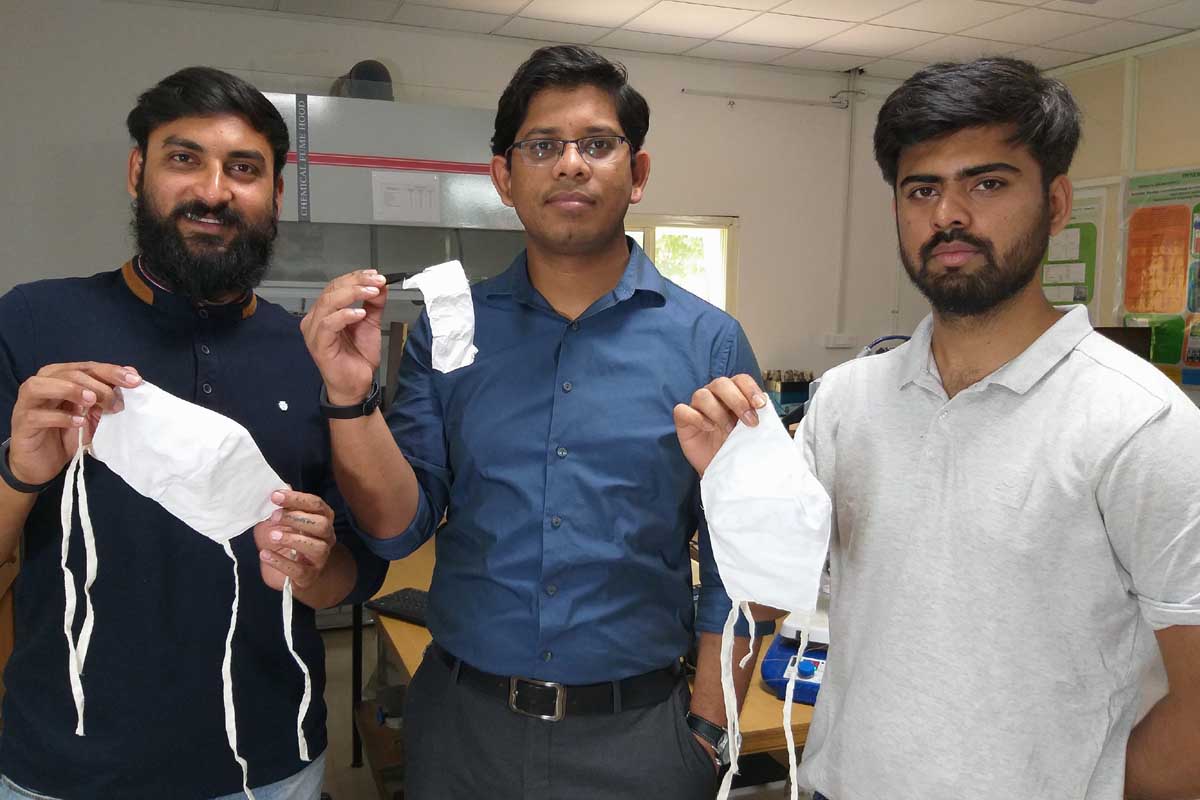

A team of IIT Mandi researchers including Sumit Sinha Ray, Assistant Professor, at School of Engineering and his research scholars Ashish Kakoria and Sheshang Singh Chandel have come-up with new indigenous technology to make face masks.

Advertisement

The researchers used waste plastic bottles to develop a single thin layer of nano-nonwoven membrane that provides desirable particle filtration efficiency, at par with N95 respirator and a medical mask.

The product has been developed and tested in the Multi-scale Fabrication and Nanotechnology Laboratory at IIT Mandi.

Sumit Sinha Ray said a human hair is close to 50 micrometres (0.05 mm) thick, the nano-fibre membrane developed at IIT Mandi contains fibres which are 250 times thinner than a human hair.

A single thin layer of nano-nonwoven membrane used in the masks developed by the research team can remove particles from the air at the critical size of 0.3 micron with more than 98 percent efficiency. These particles are also called the most penetrating particle and are the most difficult to catch.

With this, the researchers envisage replacing the commercially available melt-blown fabric masks which contain microfibre with these ultra-fine nanofibre based masks.

“Nanofibres can do wonders for face masks. Air-borne particulate and pollutant removal efficiency and breathability are two main criteria for efficient face masks.

Commercially available melt blown fabric-based masks can be efficient at a cost of high breathing resistance whereas generic 3-ply surgical masks are breathable but have meagre efficiency.

Nanofibres based masks can filter out small particles effectively despite being comfortably breathable. We hope to find interested industrial partners to take this technology for large scale production,” he added.

To achieve this, Ray and his team used ‘Electrospinning’ in which the researchers shredded the waste plastic bottles (PET) and dissolved the pieces using a combination of solvents and extruded the nano-fibres from the solution.

These nanofibres meet the safety requirements of the user by excluding the bacteria and infectious components. The breathability in the developed masks is better than the commercially available masks.

Ray has filed a provisional patent for the waste plastic bottle derived filter membrane technology based on electrospinning.

At the laboratory scale, the material cost for the mask can be around Rs 25 per piece but during the commercial manufacturing stage, its cost will be nearly halved.

Ashish Kakoria, research scholar said, “These ultrafine fibres allow less resistance in airflow due to a unique phenomenon, what we call as the ‘slip flow’, which improves breathability.

Moreover, the thrown away PET bottles can be put to good use using this technique.”

Apart from this, the research teams had also developed an efficient nanofibre incorporating a 3-ply semi reusable mask using a membrane made out of Nylon which boasts free-standing nano-nonwoven architecture.

These masks are more efficient than 3-ply medical face masks in capturing airborne particulates at a similar breathability scale.